The way this last year has gone, most people are seeing more parcels through the door than ever, with shops closed and distance in order. However, buying online often means single use packaging, which makes us think as the boxes stack up, what is happening to all those parcel bags? We talk to you about what matters when it comes to packaging and share the care we put into getting our garments safely to you door with minimum environment effect.

We’re all to aware of the short and long-term damage that plastic bags do to our planet and while governments are slowly bringing in regulation to keep businesses under check, for now its in the hands of the makers. Australia by 2025, for example, will be demanding that 100% of packaging be reusable, recyclable or compostable; let's hope the UK makes a bigger move soon. Until then, businesses have to make important choices about how to wrap their products.

Compostable vs Home Compostable

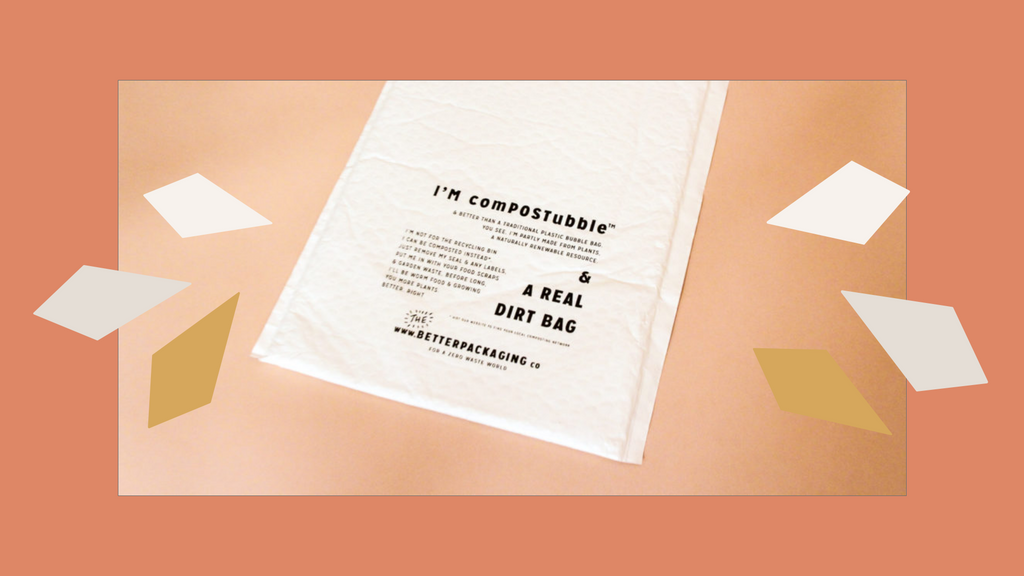

While you may see compostable on your packaging, this still often means that, whether natural looking or not, it is required to be taken to an industrial facility where high temperatures and energy intensive processes far from town are used to break down your bags. Luckily, our parcel bags are made by the high tech guru Better Packaging Co meaning they’re natural at heart and can be places straight into your home recycling bin to be fed back into the ground before you know it.

Home compostable also means it reaches a higher environmental standard, passing rigorous worm toxicity tests, all components including the printing ink and adhesives must be able to decompose into organic soil.

Labels Too!

We also went the extra mile when it comes to our packing, doing the research and only sourcing tested materials. The FSC forrest management standards makes sure the printed tissue paper used comes from responsibly managed supply chains, which help build on livelihoods not destroy them.

Acid free papers means that no chemicals will be left behind and the end of life. Made specially for us from cellulose fibre, the active acid pulp is eliminated during production.

One more thing. We used soy based inks, an eco friendly alternative to the usual petroleum based type. As well as being from a sustainable source, they have low levels of VOCs, reducing air pollution while drying and still producing vibrant colours.

Track and Trace

Transparency is the future and we believe you care where your garments are made: the people that make them, their stories and their methods. We’re in the process of developing a new platform where you can track the artisans and crafts behind your clothes. But until then, read the description to learn the real value of your item and the difference it has made to someones life.

If you have any ideas on how we could do things better, would love to hear from you - thank you for reading!